At G&M Manufacturing, we are dedicated to developing innovative ways to make your precision metal stamped parts the best they can be. We operate an ISO 9001:2008 certified facility housing high speed presses up to 100 tons, each outfitted with in-die sensors and automated camera systems to guarantee the highest quality part production possible. Our services are used by customers worldwide in the automotive, electronics, electrical, industrial, consumer products, and medical industries.

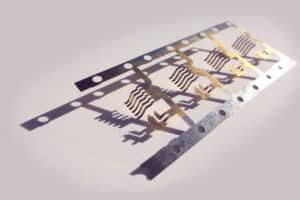

At speeds of up to 1200 parts per minute, we are able to fabricate parts from most materials, including ferrous, non-ferrous, and exotic metals, hardened super alloys, and all types of plastics. Progressive die, compound die, and draw die tooling is designed and manufactured in-house, giving us precise control over quality and keeping your costs down. We specialize in mid- to high-volume production of small to medium size parts and are capable of forming a diverse range of part geometries, from the most simple to the most intricate and complex. We are also capable of wire EDM machining, CNC milling, and waterjet cutting to offer complete turn-key tool making and prototyping services.

Finishing choices are numerous and include heat treating, powder coating, as well as variety of plating options. Parts can be supplied loose, on reels in continuous coils, or in other packaging systems. Careful attention to detail and dedication to providing the highest level of customer service is what keeps many loyal customers using our precision metal stamping services for their part fabrication needs. Contact us today to learn how we can help you with your application.